Shop floor digitalization

crafted for all team members.

Machining workshops use Tooling Metrics to implement their digital machining strategy, drive operational effectiveness and efficiency — all simplified and integrated into an easy-to-use platform.

Select a job and start a feature tour to see how Tooling Metrics supports you in getting it done. Or click below to explore what it looks like, how it works, and how it can help you.

And more are coming...

All the features

done right

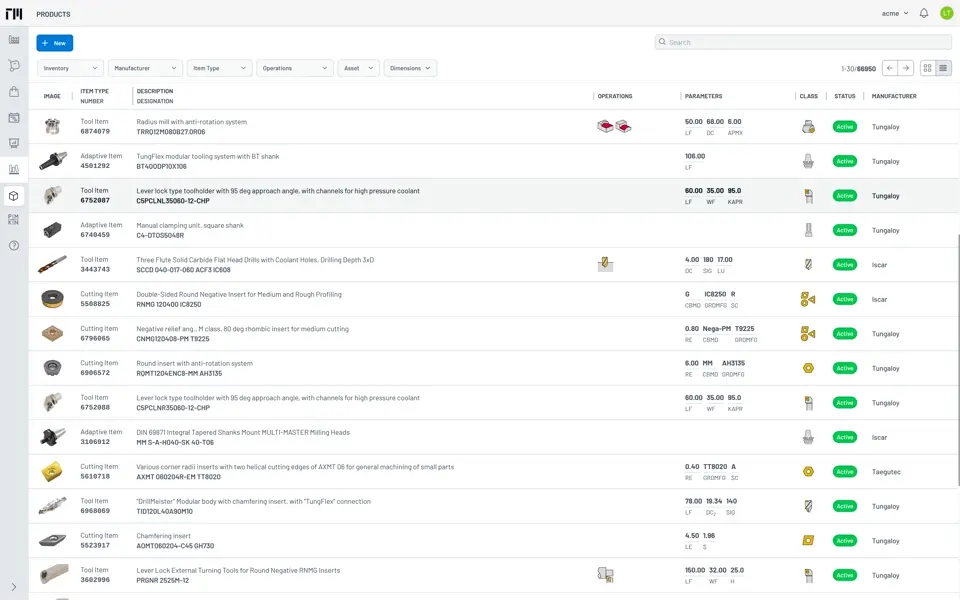

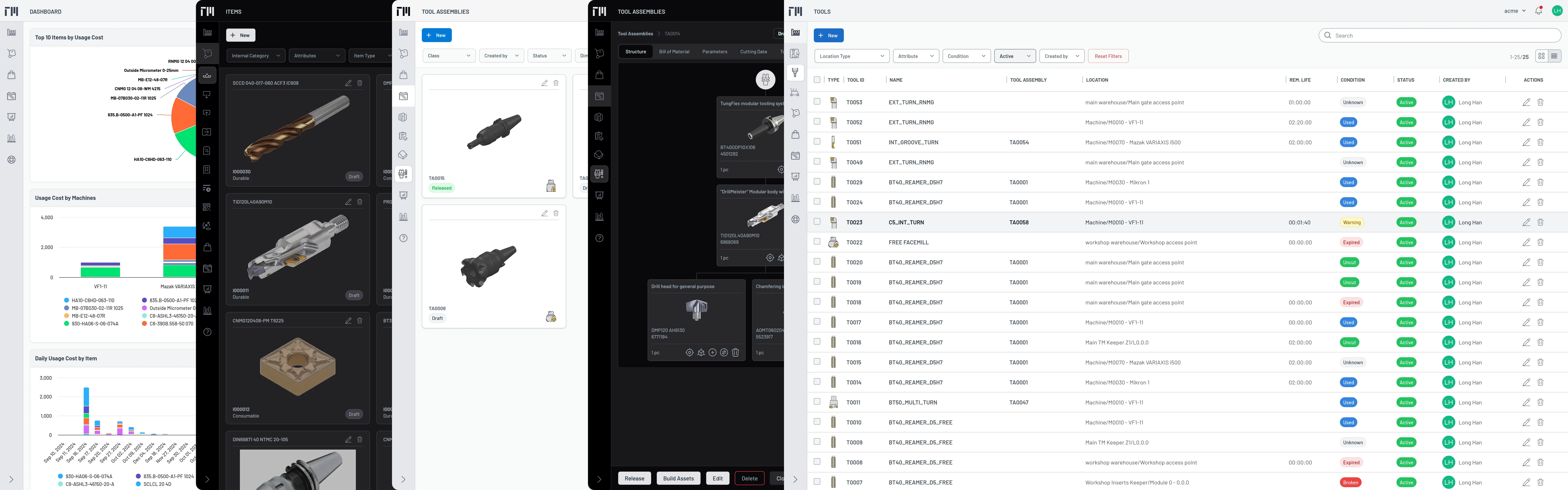

Modern user interface

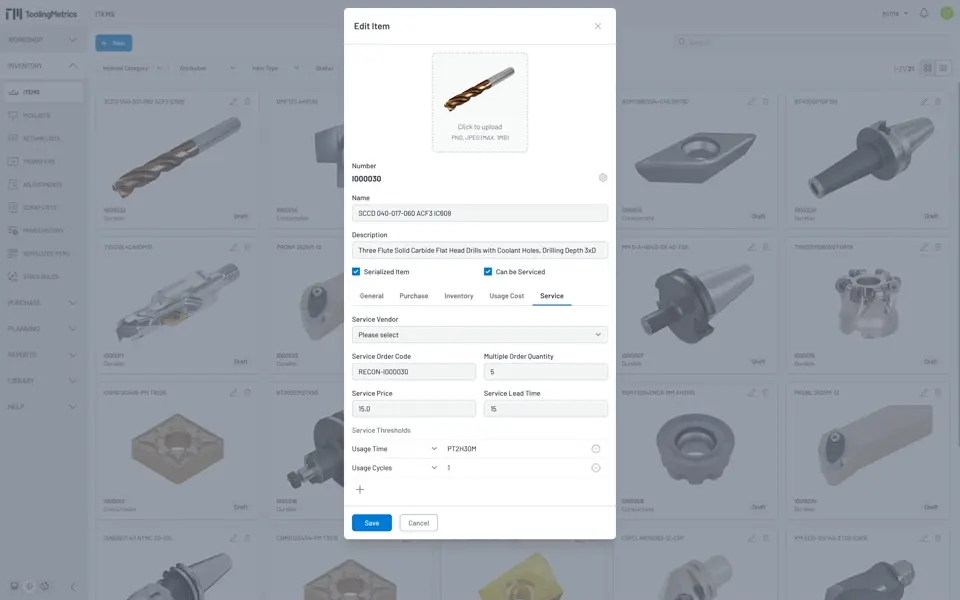

Our clean and simple web interface give you ability to access relevant data from anywhere, allowing you to accomplish your job with easy, fast and fun. We craft our products with love, drawing on years of expertise and passion in metal cutting to ensure quality and reliability.

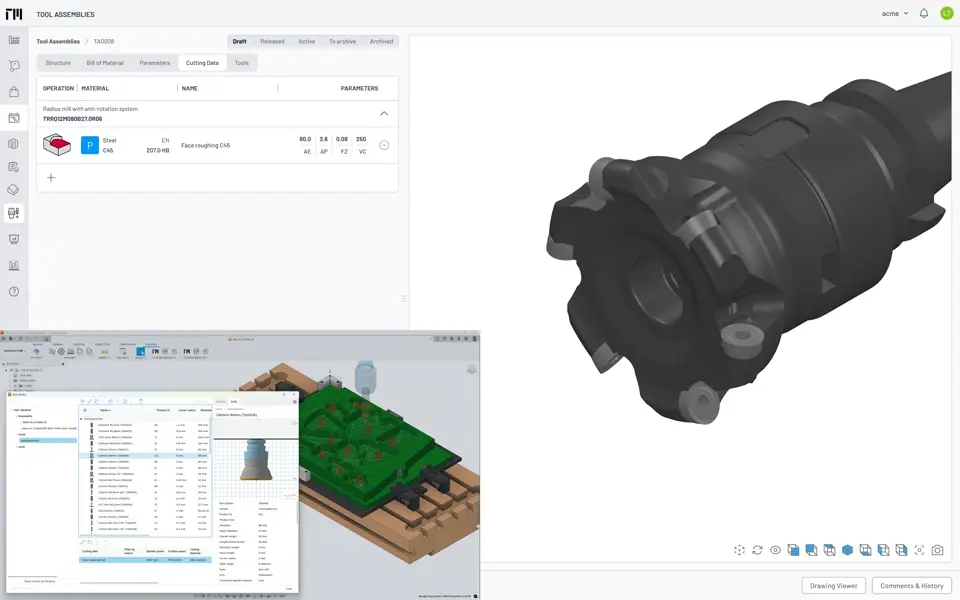

One platform for entire tool flow

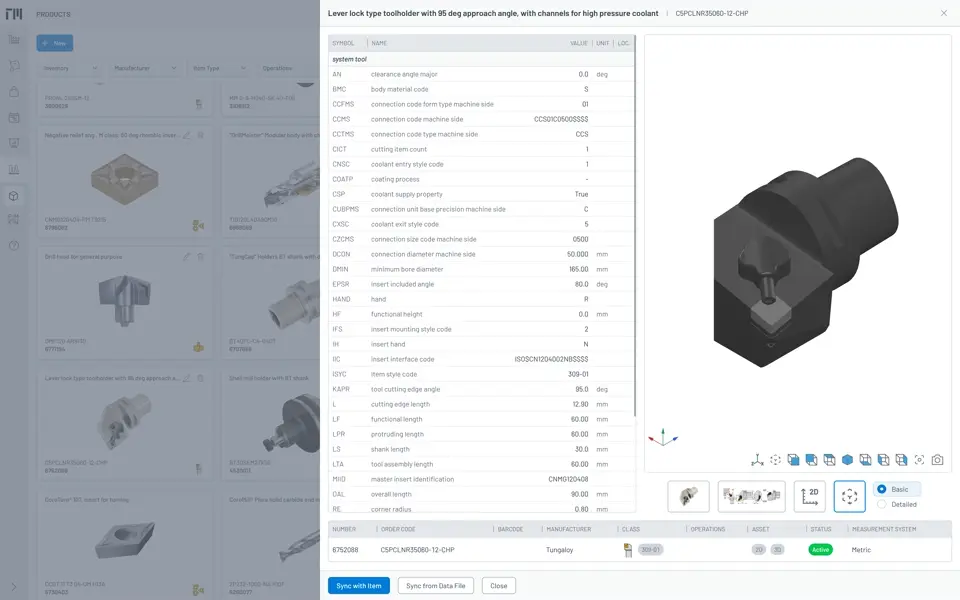

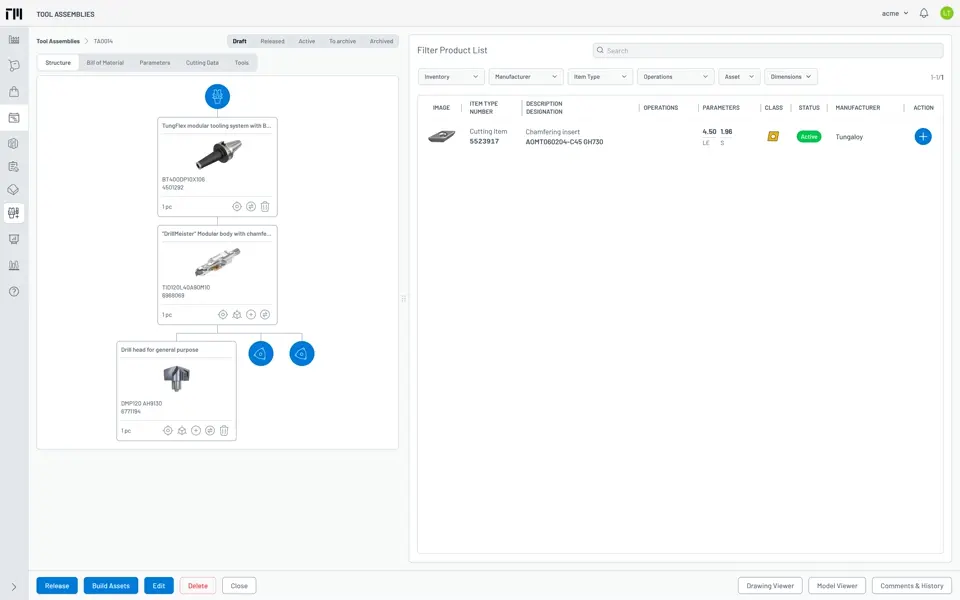

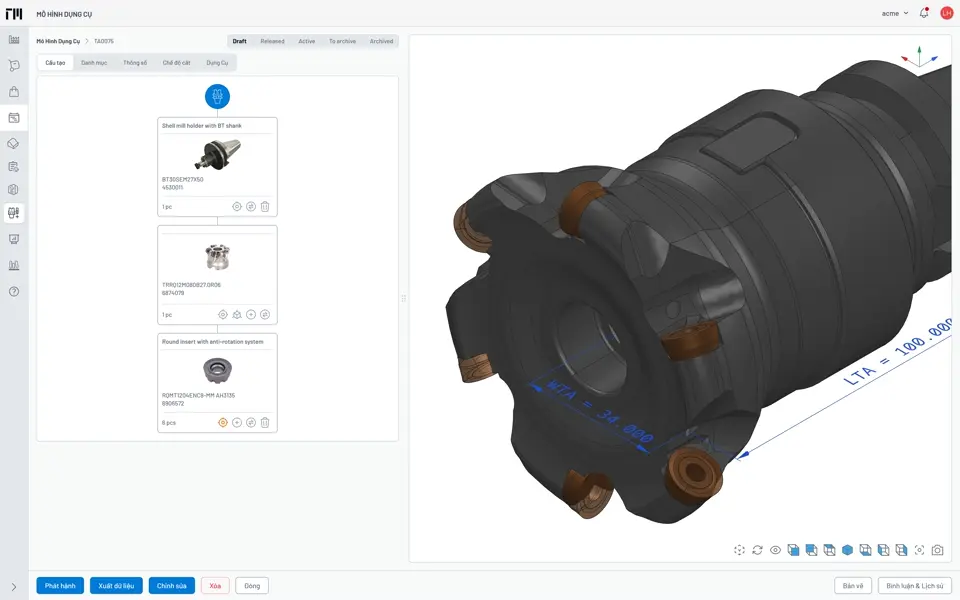

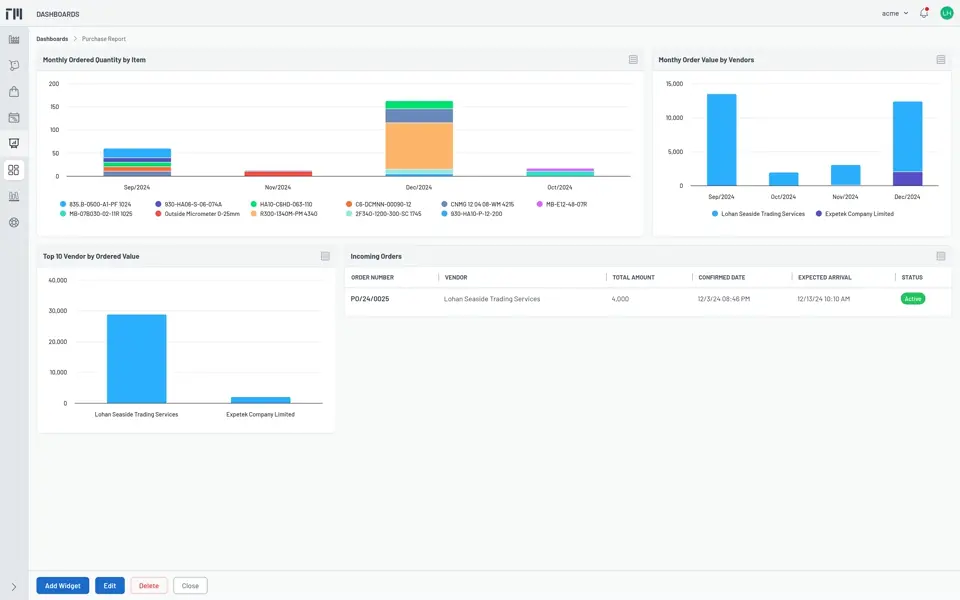

With Tooling Metrics, you can accomplish almost every task in the digital tool flow while enriching your tool digital twin throughout its lifecycle. Capture key aspects like assembly history, usage, condition, cost, and tool life. This data is automatically analyzed in a powerful reporting engine, presented in an actionable dashboard that helps you make informed improvement decisions with your colleagues, vendors, and manufacturers.

Tool Management Software, redefined!

Tool management software used to make sense only for large manufacturers. But not anymore, we bring a simple, efficient, and yet affordable solution to all, even a "one-person" machine shop. Be prepared for the future when expanding your workshop or setting up a new production site without worrying about upgrading your TMS.

Enterprise software done right

No more confusion or frustration with pricing, packages, or hidden paid add-ins. With a fair and simple pricing plan, you’ll always have access to every feature of an advanced and sophisticated tool management software, empowering you to fully digitalize your machine shop.

Start using now

return in a month

Cut time from CAD to part

Getting the first article in your hand in much faster thanks to a centralized, real-time updated tools library for all team members to access the tool data they need, helping them collaborate efficiently on planning and execution an optimal process.

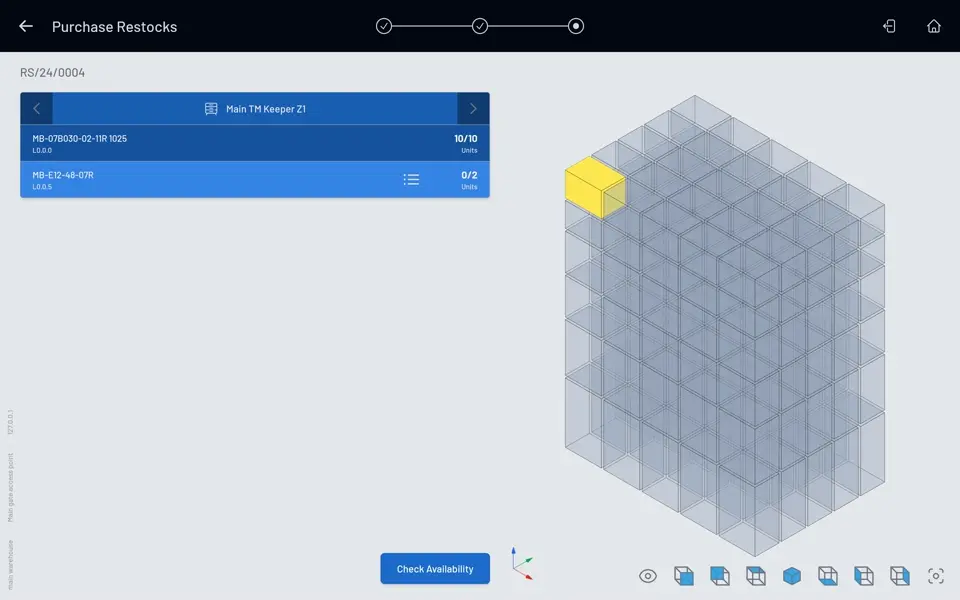

- Real-time inventory insight: Instantly know what’s available or what needs ordering during process planning or later before setup trial cuts.

- Quick tool access: Locate the right tool or receive guidance to assemble a new tool within minutes, reduce search and setup times.

- Digital twin creation: Quickly create 3D models for simulation and verification, enabling faster setup.

- Automated workflows: Digitize tool planning and workflows to eliminate manual steps and minimize delays.

Deliver the highest quality

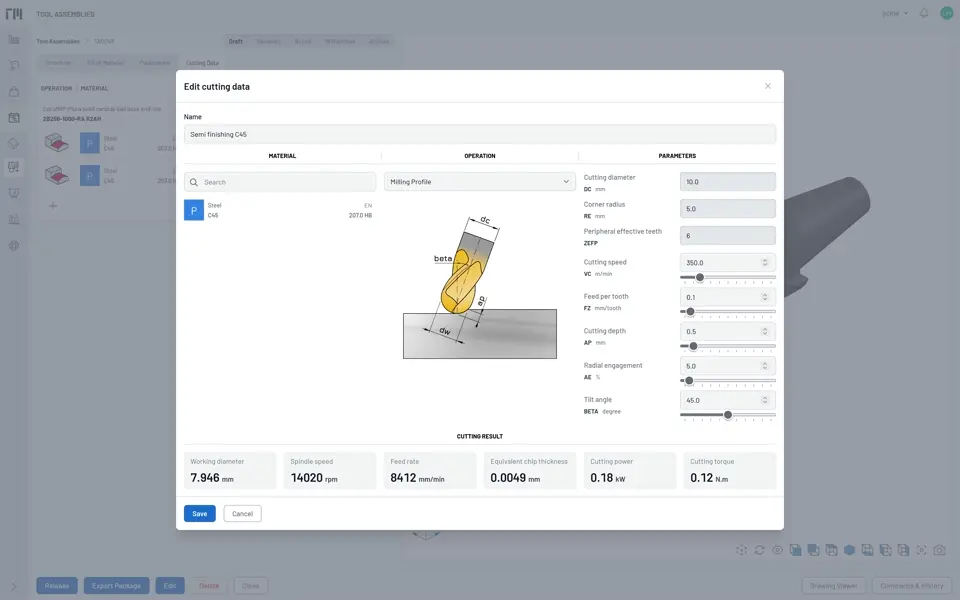

Ensure secure and reliable manufacturing processes with precise toolpath simulation, verification, optimal cutting data, error-free setup, and continuous tool life monitoring in a transparent system. This combination guarantees the highest quality standards for every part produced.

- Enhanced part quality: Optimize cutting parameters and maintain quality assurance with reproducible processes.

- Reduced scrap and rework: Identify potential issues early like prevents collisions, tool breakage to lower scrap rates and maintain consistency.

- Stable and transparent processes: Consistent tool data and reliable machining operations ensures stable and transparent manufacturing processes.

Boost productivity throughout the tool flow

Increase production output by minimizing machine downtime with the right tool in the right place at the right time. Maximize machine OEE and tool circulation by having sister tools ready just in time. Simplify operations by eliminating tedious manual data entry with a connected tool flow, from digital twin creation to tool life monitoring.

- Avoid machine downtimes: Ensure timely preparation of sister tools, keeping machines running at peak productivity without tool collisions or breakages.

- Quick adaptation to changes: Easily respond to in production reschedule with a transparent view of all tool resources.

- Paperless and connected: Automate and integrate processes in a paperless environment, ensuring smooth workflows.

- Custom dashboards: Access essential information at a glance for fast, informed decision-making.

Save money throughout the tool life cycle

Optimal cutting data and comprehensive tracking of tool life and usage enable you to extend tool life, maximize usage, and minimize stock variety. Identify and eliminate unused tools to reduce inventory costs and handling expenses, resulting in continuous cost savings throughout the tool life cycle.

- Reduced inventory and handling costs: Only keep essential tools in stock, lowering storage and handling expenses.

- Extended tool life: Optimize cutting speeds and feeds to maximize tool life, result in reducing tool costs.

- Lower cost per part: Efficient, stable processes and optimal tool life cut costs per part, boosting profitability.

- Reduced cycle time: Faster cycle times allow for more parts per hour, decreasing overall production costs.

Get job done easier, faster, and more enjoyably

Work smarter with intuitive access to the right tools and data at every step. A digital, paperless environment streamlines workflows, so tasks are simpler and faster. With all resources in view and guided processes, team members can complete jobs with ease and confidence, making work more efficient and enjoyable.

- Simplified tool access: Quickly find the right tools or guidance to assemble tools, reducing search time and frustration.

- Automate and intuitive workflows: Say goodbye to repetitive, tedious tasks. With just a few clicks, you can easily access the right data to complete your tasks with intuitive guidance.

- Paperless, digital environment: Work with digital processes that streamline tasks and save time.

- Increased transparency and visibility: View all tools location, condition, cost, usage history, tool life history in real-time, enabling a more intuitive, enjoyable workflow.

Gain Competitive Advantages for Sustainable Growth

Achieve a competitive edge with data-driven insights, centralized knowledge, and consistent quality standards across all operations. Digital twins and structured data bring process reliability, while continuous improvement strategies allow for sustainable growth. With complete transparency and harmonized data, you can respond quickly to changes, staying lean and ahead of the industry curve.

- Data-driven decisions: Leverage tool data and structured insights to maintain a competitive edge in efficiency and quality.

- Company-wide knowledge base: Build a centralized repository of machining knowledge to lever up your machinist expertise and continue improve production quality, productivity and cost.

- Digital transformation and innovation: Use digital twins and transparent workflows to stay ahead of industry trends.

- Global data harmonization: Maintain consistent data and quality standards across all production sites for sustainable growth.

boost productivity

and cut cost

No obligation, no credit card required.

Instant access