Machining Calculator

Cutting Parameters & Machining Results

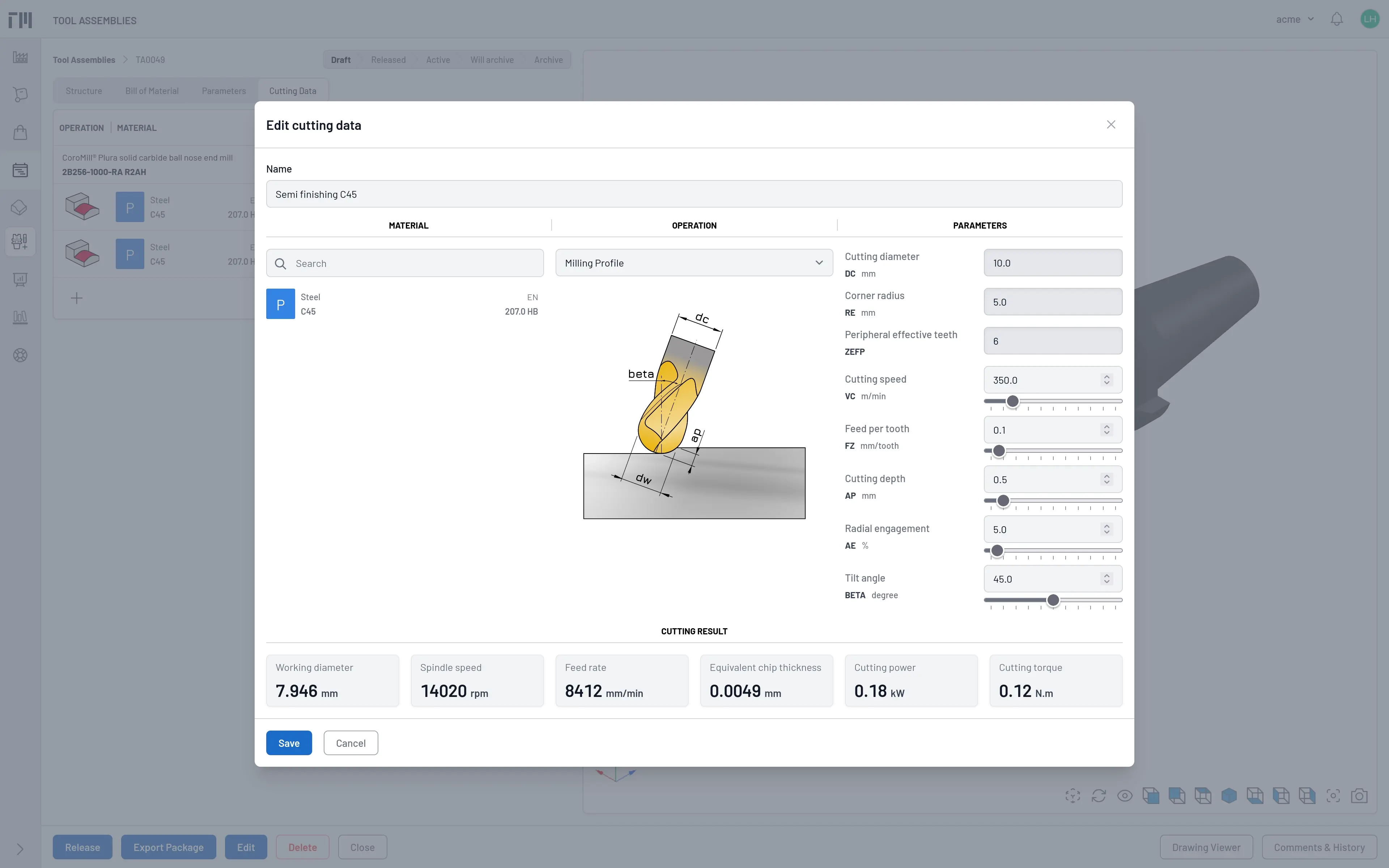

Cutting data is one of a valuable asset of a machining workshop. Your machining result will be much different if you have a suitable one. With Tooling Metrics, all of your cutting data will be managed within each Tool Assembly, let you create/find/update those cutting parameters at every stage of it’s lifecycle. Not only that, our Machining Calculator help you quickly get the estimation of the cutting results, and plan your tooling requirements and other machining resources better.

These cutting result is provided as it is base on the theoretical values & research and are only intended for planning purposes. Actual results will vary. No responsibility from Tooling Metrics is assumed.

Cutting parameters is different when you apply the same tool to different workpiece material and/or operation. Tooling Metrics allows you to save cutting parameters directly into your Tool Assembly.

Each cutting data can be assign to difference material, and supported cutting operations.

Automatic gets required data from your Tool Assembly parameters, so you don’t have to manually input.

Intuitive and easy to adjust the cutting parameters with number or slider input. The parameter ranges are also take account from the Tool Assembly parameters.

Cutting Result is dynamically recalculate whenever any of one adjustable parameter was changed.

Get the basic cutting results like working diameter, speeds & feeds. Also, some advanced one as equivalent chip thickness, cutting force, torque, and cutting power.

Export to CAM software inside the CAM packages, let you easily apply cutting parameters to your machining operation.