Tool Assemblies

Build Complete Tool Assembly

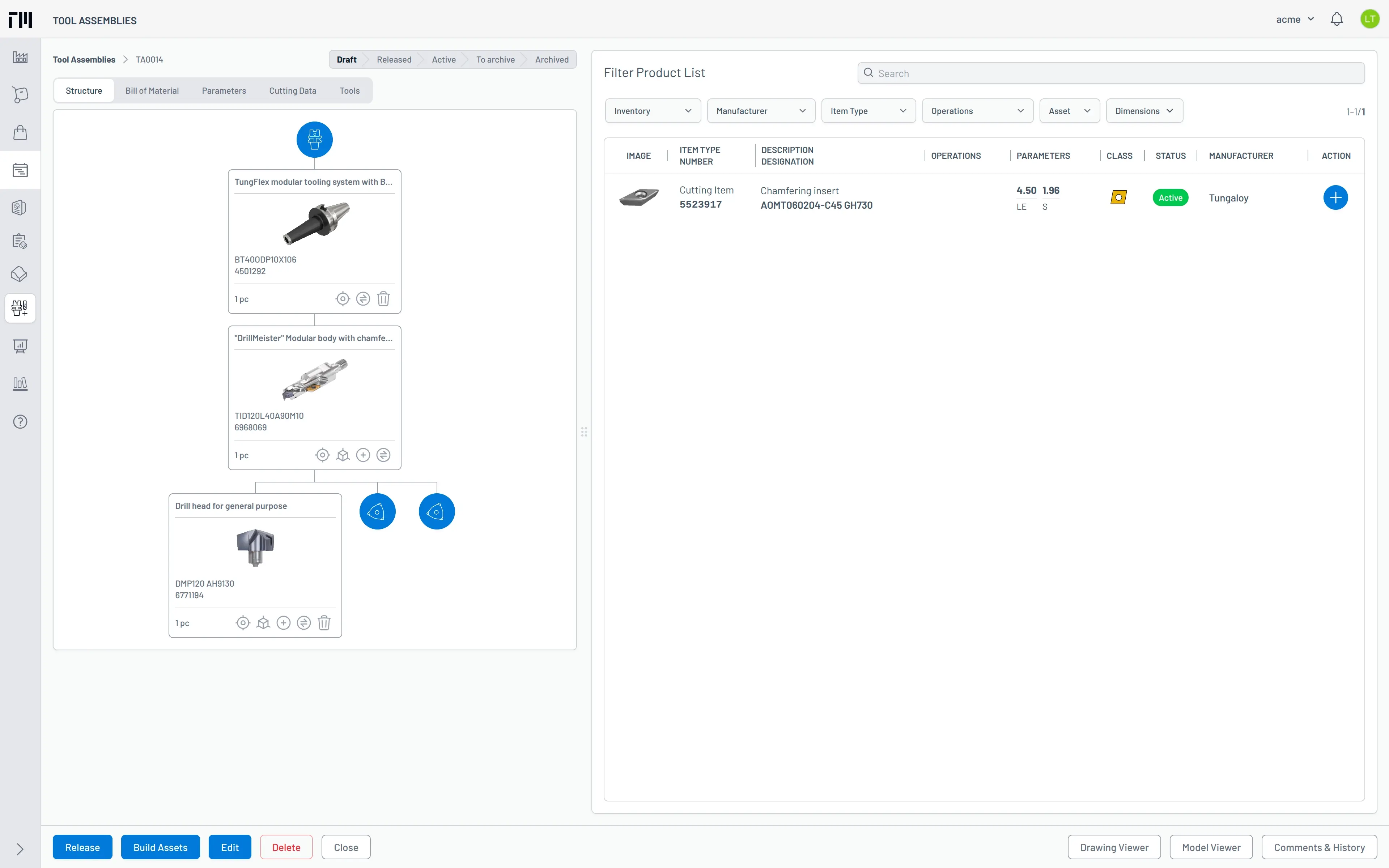

Creating a precise and complete tool assembly in a short timeframe can be challenging. Tooling Metrics simplifies this process. Begin by selecting items from your inventory or our extensive generic tool catalog. Assemble up your tools with confidence, ensuring compatibility across multiple manufacturers using our automatic matching connection code.

All trademarks, logos, and brand names displayed on the product are the property of their respective manufacturers. They are used solely for identification and informational purposes. Use of these trademarks does not imply any affiliation with or endorsement by their owners.

Finding your optimal tooling product never get such easy and fast. Just by selecting the machine or workpiece side, all compatible products will appear right there for further searching and/or filtering, no matter what manufacturers.

Quickly adjust the effective tool length, or exchange a product at middle position is convenient.

Looking for how to assembly, you got Structure tab. What’s products included? The Item list tab shows you, detailed to spare parts. Make a NC program by hand? The Parameters give the relevant one.

Automatic generate assembled drawing, 3D models files from product data assets.

Building a complete assembly model for CAM preparation is just the beginning. Tooling Metrics allow you to integrate it digital twin seamlessly throughout your entire digital thread—from planning and purchasing to stocking, assembly, presetting, production, monitoring, inventory control. Then analytics for continuous improvement—ensuring smooth operations and maximum efficiency.