Tool flow digitalization

crafted for your machine shop.

Tooling Metrics is the tool management platform that supports your digital machining, all the way from process design and planning to in-machining and machining analysis.

How it works,

throughout tool flow.

1

Digitalize each warehouse, from storage locations, storage modules, storage devices, up to warehouse access points. Assign each location a unique address, name, position, and realistic 3D model.

2

Upload your item data and/or synchronize your items with our Generic Tool Catalog. Categorize items into internal categories with a sophisticated, configurable cost allocation method.

3

Start your initial inventory by counting item physical quantities and costs. Choose which items are serialized and/or serviceable. Place each item in its preferred storage location.

4

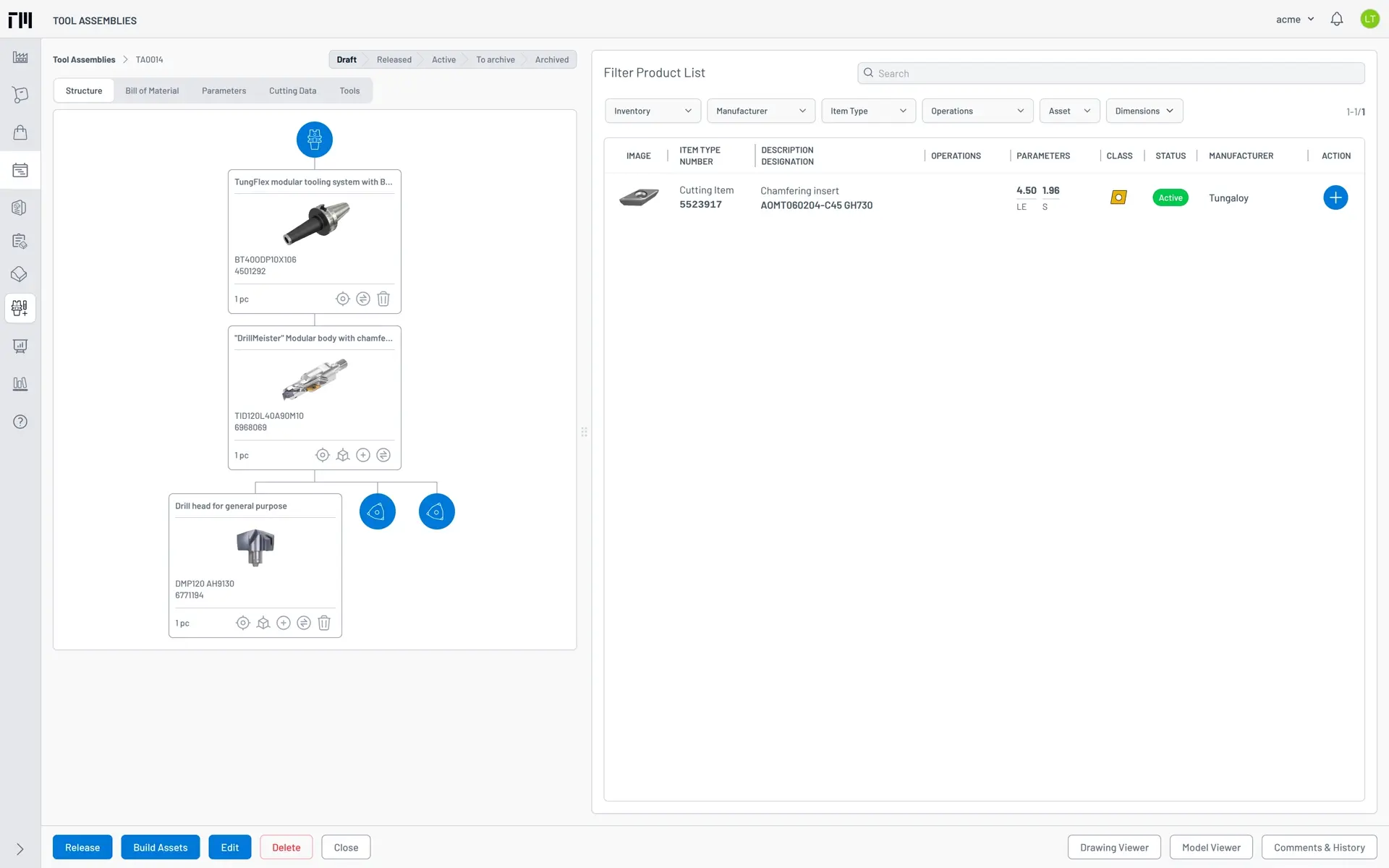

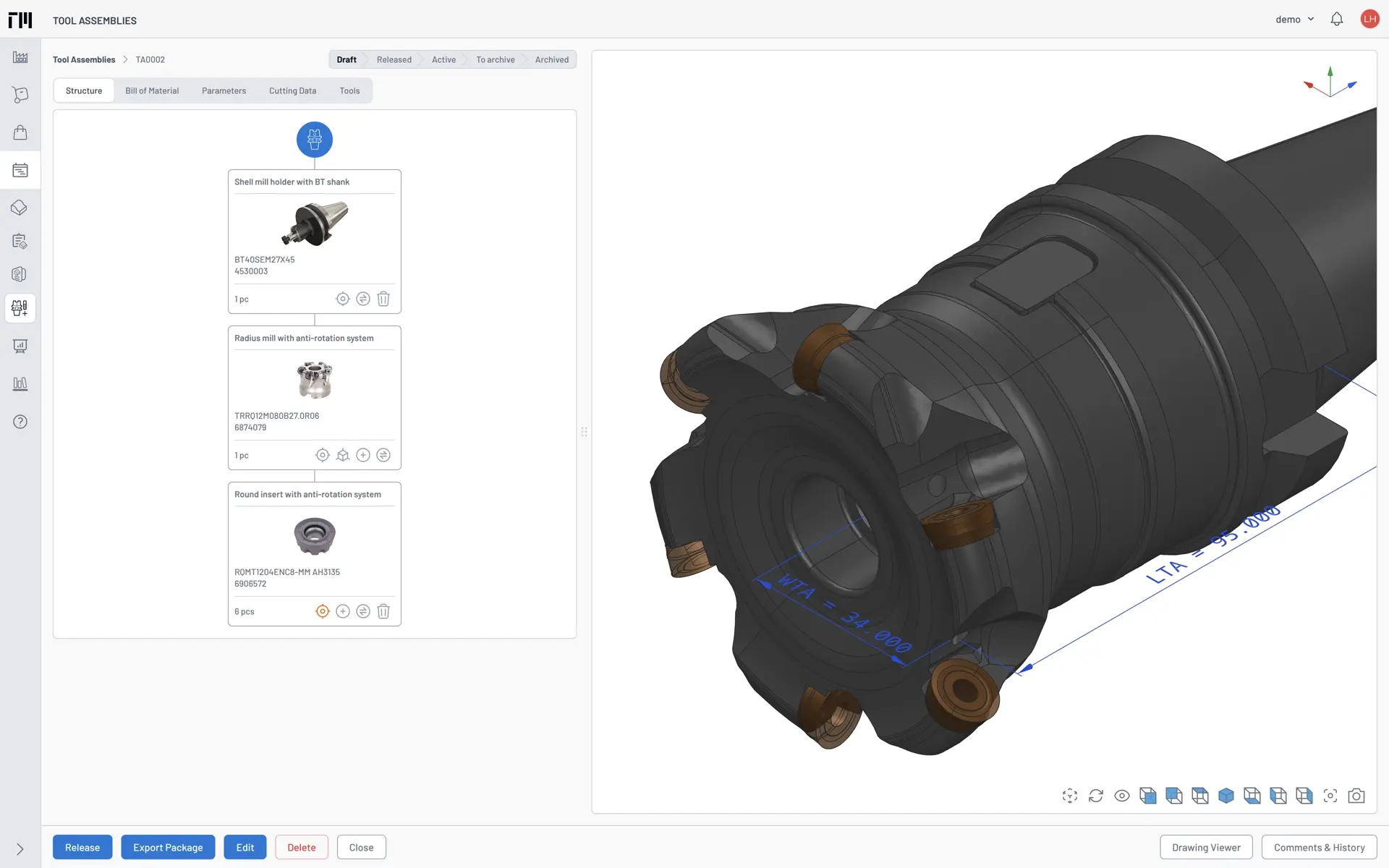

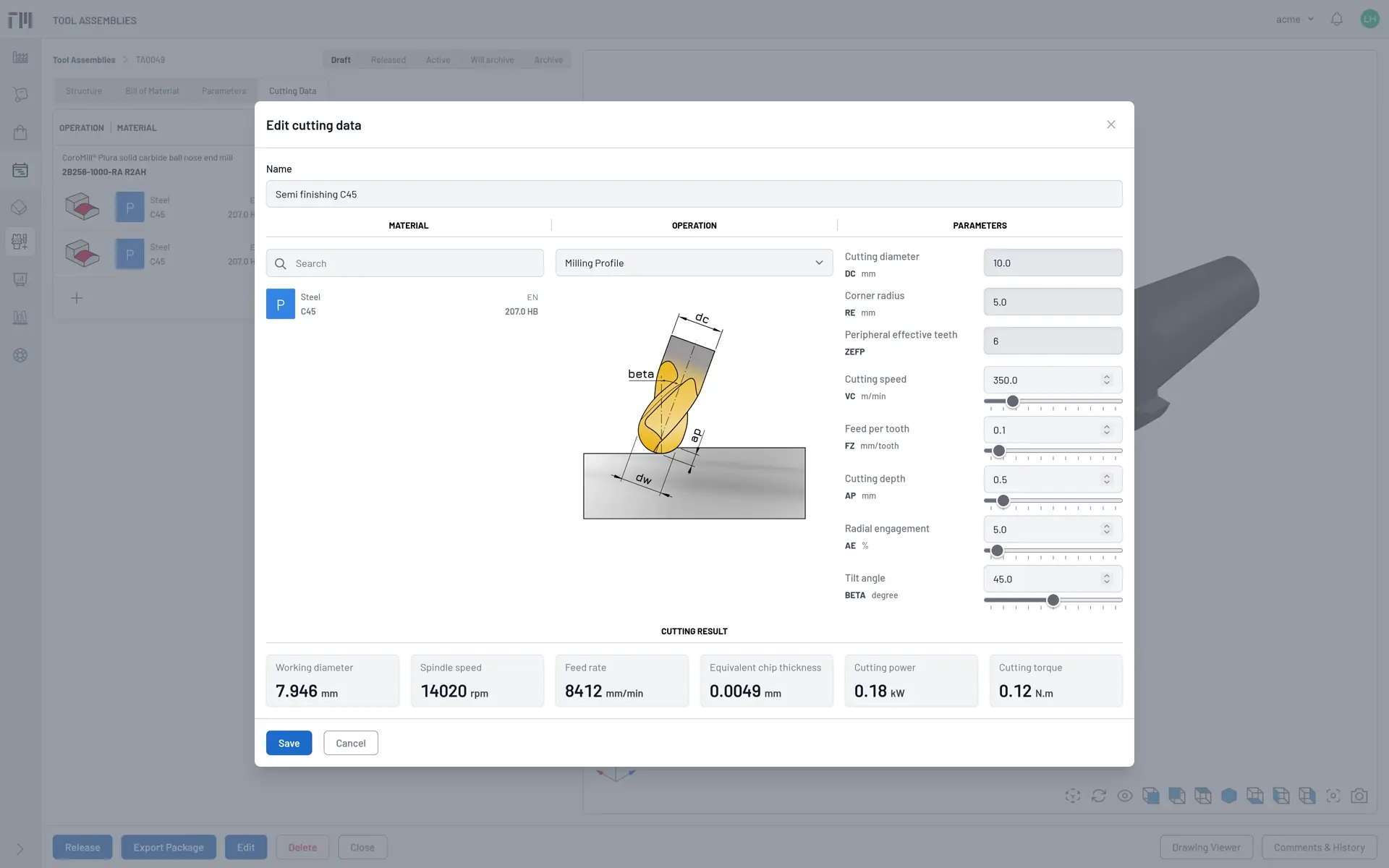

Build your tool digital twin library from either your inventory or manufacturer products. Calculate cutting parameters and estimate machining results for each operation and material.

5

Export the tool assemblies library to your preferred CAM software for toolpath generation, simulation, and verification. Send data to the workshop and its BOM to inventory and purchasing with one click.

6

Upload a vendor list, create reordering rules, and run auto-procurement to generate and send RFQs to assigned vendors. Confirm POs to track incoming and forecasted quantities, both in warehouse and in shop floor.

7

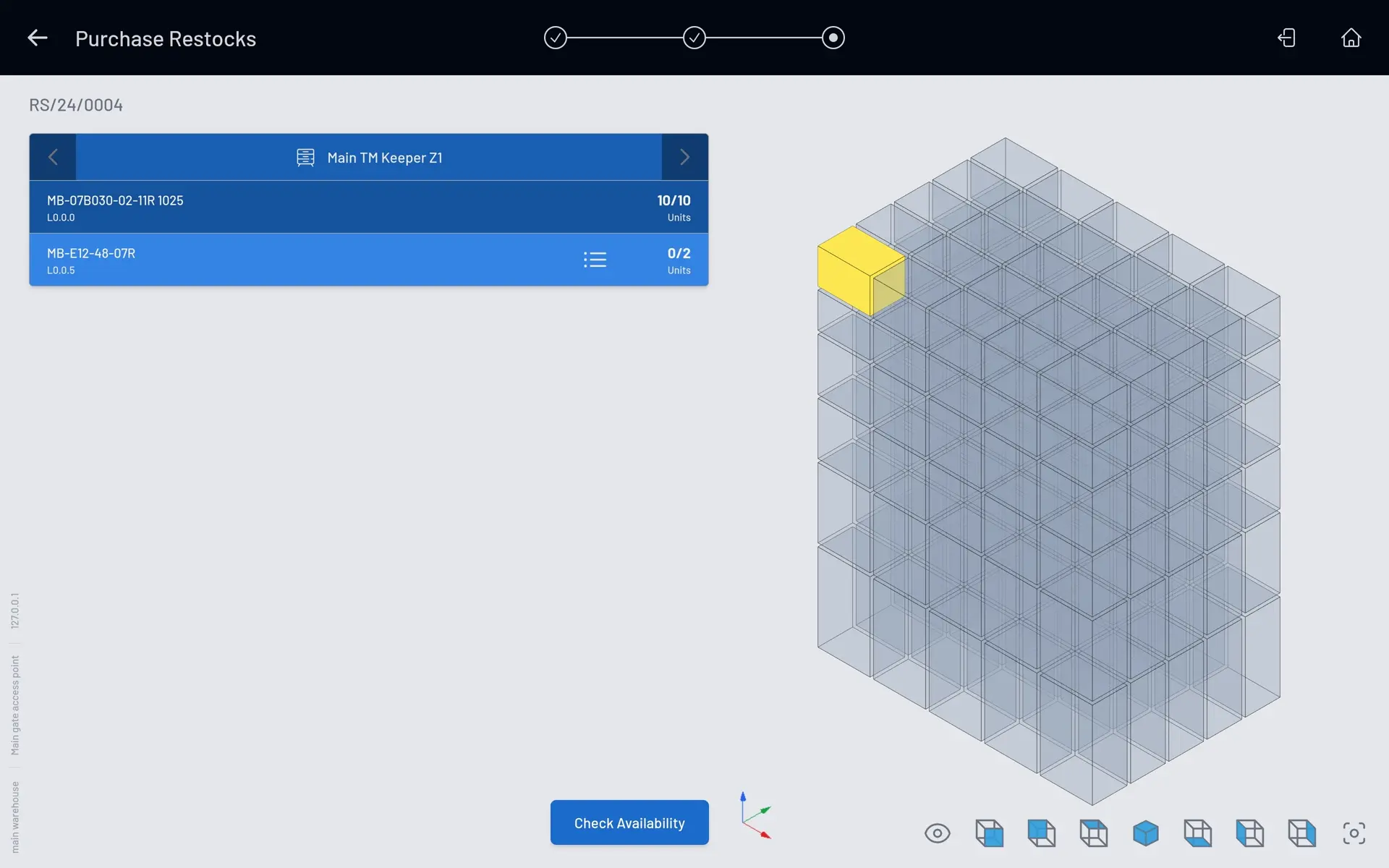

Receive and restock ordered goods from vendors into preferred locations with detailed instructions in a few clicks, even without automated storage devices. Goods returns can also be processed and tracked.

8

Assemble a new tool with detailed guidance on which items to use, how many, and where to pick them, eliminating the need to search. Access visual assembly instructions at your fingertips.

9

Transfer newly assembled tools directly, pick existing tools from storage locations to the machine, or put back them to the storage location for none-stop machining preparation or reservation for scheduled jobs.

10

Track tool life, condition, and cost throughout its lifecycle. Automatically allocate and post usage costs with flexible and precise. Allow to pick individual item direct to machine is suitable to manage MRO items as well.

11

Disassemble worn-out items in expired tools to return them to inventory for reconditioning with a service order, or scrap broken items if tool has been marked as broken. Track conditions and costs for each serial number.

12

Get any tooling metrics that matter to your shop, all customizable from template dashboards. Set unique default dashboard for each team member, enabling them to proactively manage required tasks, in time.

Explore top

features

Unlock team potential,

unleash growth

- Deliver the highest quality while preventing machine downtimes, reducing cycle times, and cutting costs throughout the tool flow, so you can win more business.

- Automate and simplify workflows throughout the tool flow and lifecycle, making jobs effortless and enjoyable for everyone.

- Get real-time reports and dashboards for any tooling metrics, enabling data-driven decisions and timely action.

- Increase production traceability, transparency, and visibility of tooling resources to meet the highest regulatory compliance and standards.

- Quickly adapt to changes, stay lean, and gain competitive edges for sustainable growth.

- Create and optimize CNC programs faster with a central digital twin tool library integrated with your CAM software, ensuring smooth toolpath execution on the machine.

- Quickly and easily pick and assemble the correct tools with detailed instructions from the digital twin 3D model.

- No more searching for tools around the shop floor—know what you have, where it is, and in what condition with just a click.

- Tool lifecycle data reliability and transparency make it easy to plan, test, and benchmark for productivity and cost improvement projects.

- Gain machining expertise and knowledge with a company-wide cutting parameters database.

- Accelerate your sourcing and procurement process by eliminating tedious manual data entry, easily sending accurate and complete RFQs, and automating procurement and goods handling. Timely resupply what you actually need faster, ensuring you never run out of stock

- Access real-time individual items or completed tool data including inventory on-hand, incoming/outgoing, forecasted quantities, as well as their condition, cost, and exact locations based on confirmed purchase orders and production schedules.

- Efficiently handle inventory picks, returns, transfers, inventory counts, purchase receipts, restocks, or returns—quickly and easily using an intuitive, easy-to-use WAP interface.

- Track and trace any past stock movements or make reservations for scheduled jobs. Auto-generate reports on inventory valuations and tool consumption.

boost productivity

and cut cost

No obligation, no credit card required.

Instant access