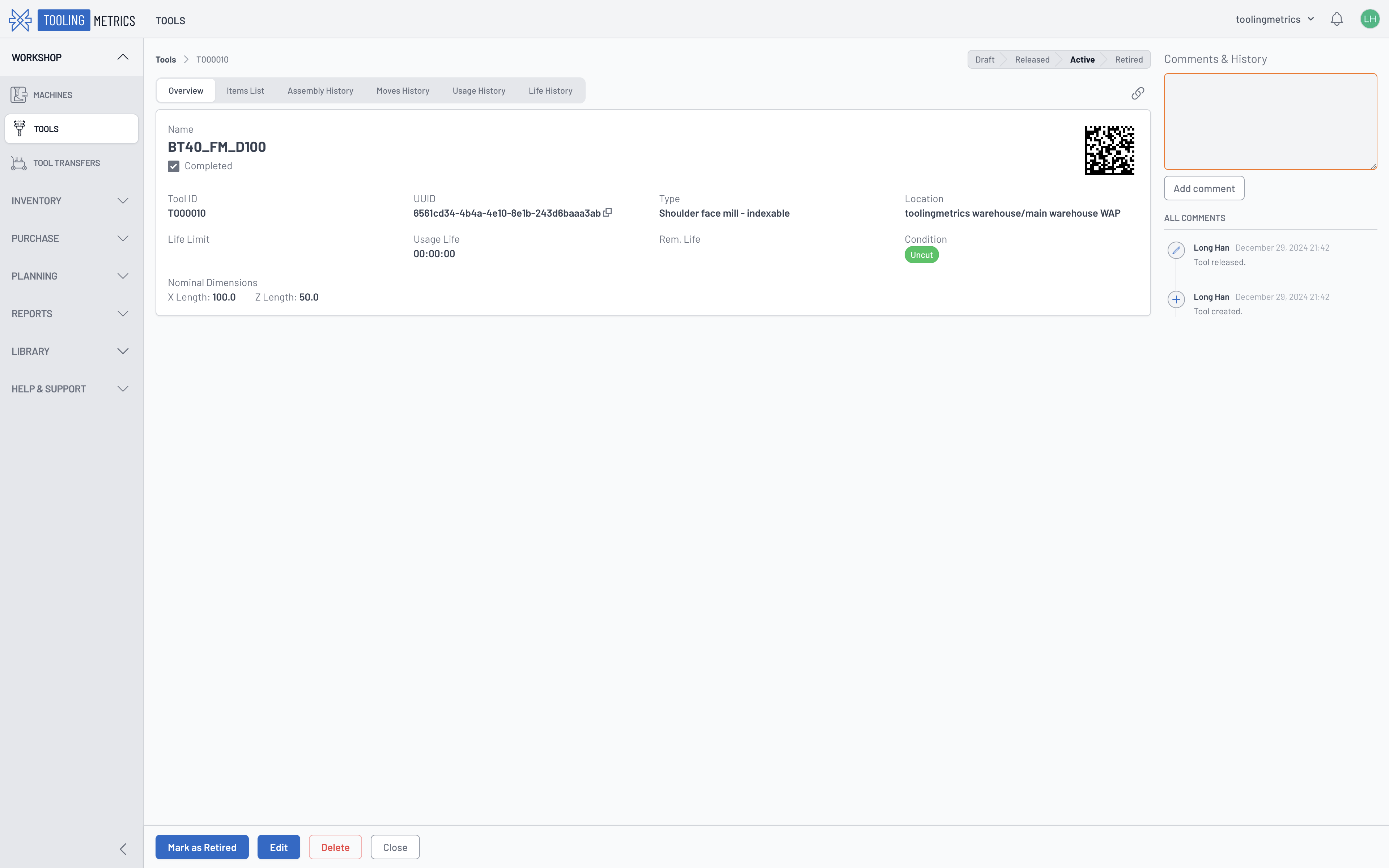

As we approach the end of 2024, we are thrilled to announce the initial release of the Cutting Tool Digital Twin, fulfilling our promise from earlier this year. Now, you can access the complete tool assembly as realized on the shop floor. This feature allows you to answer all tooling resource questions related to current items, location, condition, and track the history of assembly, movements, usage, and most importantly, tool life throughout its lifecycle.

When you create a tool assembly from various manufacturers’ product data and assets, you get a complete cutting tool as it is designed. Its 3D model, drawing, and properties are all nominal dimensions, aiding you in the process planning stage.

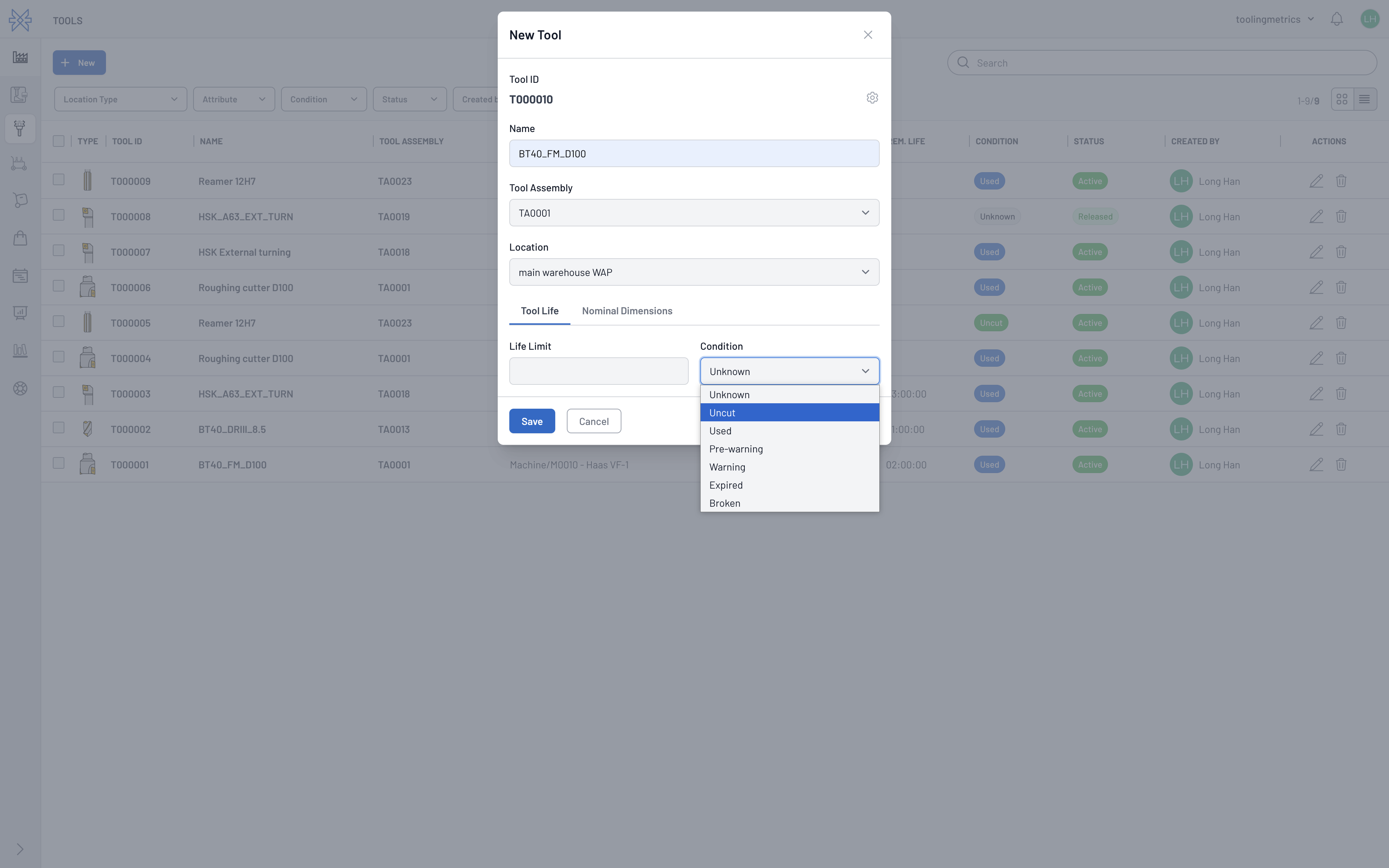

On the shop floor, the tool assembly can only refer to its designed state. Toolroom personnel, machinists, and operators can use the assembly structure and BOM data to quickly identify what and how to assemble their desired complete tool. This makes creating a new tool easy and fast by simply selecting the tool assembly it refers to.

Leveraging data from the reference tool assembly makes tooling jobs extremely fast and easy:

- Pick items in the warehouse and assemble the complete tool ready for transfer to the machines.

- Refer to tool models, drawings, assembly structures, BOM, cutting data, and cutting point references directly on the tool detail.

- Disassemble or scrap items either at the tool station or at the machines.

- Move tools from storage locations to machines or tool stations to replace worn-out/end-of-life items. Return tools from machines/tool stations to storage locations. All assembly and movement history is tracked.

- Locate the right tool by heading to machines, tool stations, or storage locations. Track the item/serialized item location when it’s assembled in a tool.

- Automatically track individual item usage costs when tools are involved in pick/return/scrap actions.

- Automatically update tool completeness and cutting edge condition (based on serialized item condition) when picklist/return list/scrap list is validated.

- Automatically trigger a service order when a serviceable item reaches predefined service thresholds.

- Manually update usage life when returning tools from machines to storage locations.

- Set life limits, get remaining life, and analyze data with a powerful yet customizable dashboard for easy benchmarking of new tool improvement trials.

With this update, your team can accomplish almost every task in the digital tool flow while enriching your tool digital twin throughout its lifecycle. More importantly, the collected data can be analyzed to provide insights into the efficiency and effectiveness of your machine shop’s use of tooling resources. This helps all team members boost productivity and reduce costs with real actions on the shop floor.

Thank you for your continued support and partnership throughout the year. We look forward to achieving more milestones together in the coming year.

The Tooling Metrics Team